Baxi Bermuda Back Boiler Manual: A Comprehensive Guide

Boiler Manuals offer servicing guides and instructions for the Baxi Bermuda 552/553, covering installation, operation, and troubleshooting for propane models.

Understanding the Baxi Bermuda Back Boiler

The Baxi Bermuda is a traditional back boiler system, designed for integration behind a fireplace or within a suitable housing. These boilers are known for their reliability and efficiency when properly maintained. They are compatible with both fully pumped and gravity hot water systems, offering versatility for different home setups.

Crucially, the Baxi Bermuda comes in variations, including models specifically designed for propane gas. Understanding your specific model – 552 or 553 – is vital for correct servicing and parts replacement. Proper installation, adhering to the Benchmark Commissioning Checklist, is essential for safe and efficient operation. Regular annual servicing by a qualified engineer is highly recommended to ensure longevity and prevent potential issues.

Model Variations: Identifying Your Bermuda

The Baxi Bermuda range primarily features the 552 and 553 models, with a key distinction being fuel type. The Baxi Bermuda 552 is designed for natural gas, while the Baxi Bermuda 553 is specifically engineered for propane. Identifying your model is crucial, as using incorrect parts or servicing procedures can be dangerous and void the warranty.

Look for the model number clearly displayed on the boiler’s rating plate, typically located inside the casing. Propane firefronts are only compatible with the 553 model. Always refer to the correct manual for your specific unit. Incorrect fuel usage can lead to incomplete combustion and carbon monoxide production, emphasizing the importance of accurate identification before any maintenance or repair work.

Safety Precautions Before Servicing

Before servicing any Baxi Bermuda back boiler, always isolate the gas and electricity supply. Ensure the boiler is completely cool before commencing work. Carbon monoxide is a serious risk; a carbon monoxide detector is highly recommended in the vicinity of the appliance.

Qualified Gas Safe registered engineers should undertake all servicing and repairs. Never attempt repairs if you are not competent. Be aware of hot surfaces and potential scalding from hot water. Always follow the manual’s instructions meticulously. Proper ventilation is essential during and after servicing. Failure to adhere to these precautions could result in injury, fire, or carbon monoxide poisoning.

Locating the Manual and Documentation

The Baxi Bermuda back boiler manual and associated documentation are crucial for safe installation, operation, and servicing. Initially, check with the homeowner as they should have retained the original paperwork. If unavailable, online resources are often helpful.

Many websites archive old boiler manuals, including those for the Baxi Bermuda. Searching using the model number (e.g., 552, 553) is key. The Benchmark Commissioning Checklist is typically included with the appliance and should be kept with the documentation. Always ensure the manual you find corresponds to your specific model, particularly if it’s a propane version, as instructions differ.

Initial Setup and Commissioning

Proper initial setup and commissioning of the Baxi Bermuda back boiler are vital for efficient and safe operation. This process should always be carried out by a qualified Baxi service engineer. It involves verifying gas supply connections, ensuring correct flue operation, and setting the appropriate water pressure.

Crucially, the Benchmark Commissioning Checklist must be completed. This checklist confirms all safety checks have been performed and the boiler is functioning correctly. The boiler is suitable for both fully pumped and gravity hot water systems, requiring specific configuration during commissioning. Following the manual’s instructions precisely is paramount for optimal performance.

Benchmark Commissioning Checklist

The Benchmark Commissioning Checklist is a crucial document accompanying the Baxi Bermuda back boiler, ensuring adherence to safety standards and optimal performance. It details essential checks, including gas tightness testing, flue flow verification, and combustion analysis.

Engineers must confirm correct operation of all safety devices, proper water pressure, and accurate thermostat functionality. Completion and signing of this checklist signifies a thorough commissioning process. It’s vital to leave the completed checklist with the user for future reference and service records. This documentation is a key component of maintaining the boiler’s warranty and ensuring long-term reliability, as outlined in the manual.

Operating Instructions

The Baxi Bermuda back boiler operates using a manual control system, primarily through a thermostat knob regulating heating output. Familiarize yourself with the service tap location for maintenance access. Understanding the pilot light operation is essential; the manual details relighting procedures if extinguished.

Ensure adequate ventilation during operation. Regularly check the boiler’s pressure gauge and maintain within the recommended range. Refer to the manual for specific thermostat settings and adjustments. Proper operation ensures efficient heating and hot water supply. Always prioritize safety and consult a qualified engineer for any complex issues or concerns regarding the boiler’s functionality.

Thermostat Control Settings

The Baxi Bermuda utilizes a manual thermostat knob to adjust heating output. Rotating the knob controls the gas flow to the burner, influencing water temperature. Lower settings provide reduced heating, ideal for maintaining a consistent temperature without excessive energy consumption. Higher settings deliver increased heat output for quicker warm-up times.

Experiment with different settings to find the optimal balance between comfort and efficiency. The manual provides guidance on correlating knob positions with approximate room temperatures. Regularly check and adjust the thermostat based on external weather conditions and personal preferences. Proper thermostat control is crucial for efficient boiler operation and maintaining a comfortable living environment.

Pilot Light Operation and Relighting

The Baxi Bermuda relies on a pilot light for ignition. A consistently burning pilot ensures rapid heating when the thermostat calls for heat. If the pilot light extinguishes, the boiler will shut down. Relighting typically involves turning the control knob to the ‘Pilot’ position, pressing and holding the ignite button while simultaneously applying a flame.

Once lit, continue holding the button for a specified duration, then release. If the pilot remains lit, turn the knob to the desired operating position. Always follow the manual’s specific relighting procedure. If relighting fails repeatedly, a service engineer should inspect the pilot assembly for faults or gas supply issues.

Common Issues and Troubleshooting

Several issues can arise with the Baxi Bermuda. Low pressure problems often indicate water leaks within the system or a faulty pressure relief valve; check for visible leaks and repressurize if necessary. Pilot light failure, as detailed in the manual, may stem from a faulty thermocouple, blocked pilot jet, or gas supply interruption.

Error codes, if displayed, provide valuable diagnostic clues – consult the error code section of this guide. If issues persist, avoid attempting complex repairs yourself; contact a qualified Baxi service engineer for safe and effective troubleshooting and servicing. Ignoring problems can lead to further damage.

Low Pressure Problems

Low pressure within the Baxi Bermuda system frequently signals a leak somewhere in the central heating or hot water circuits. Thoroughly inspect all visible pipework, radiators, and the boiler itself for any signs of water dripping or dampness. A faulty pressure relief valve can also cause consistent pressure loss, requiring replacement by a qualified engineer.

Before attempting to repressurize, identify and rectify the leak. Refer to the manual for correct repressurization procedures; typically, this involves using the filling loop. Repeated pressure drops necessitate professional investigation to pinpoint hidden leaks and ensure system integrity. Ignoring low pressure can lead to reduced heating efficiency.

Pilot Light Failure

Pilot light failure on a Baxi Bermuda often stems from a faulty thermocouple, which senses the flame and allows the gas valve to remain open. A dirty or blocked pilot assembly can also prevent reliable ignition. Before relighting, ensure the gas supply is on and follow the manual’s detailed relighting procedure precisely.

If the pilot repeatedly fails to stay lit after multiple attempts, suspect a faulty thermocouple or gas valve. Do not repeatedly attempt relighting, as this can create a gas buildup. Contact a qualified Baxi service engineer for diagnosis and repair; attempting self-repair of gas components is extremely dangerous and illegal.

Servicing and Maintenance

Regular servicing is crucial for the safe and efficient operation of your Baxi Bermuda back boiler. Annual servicing, performed by a qualified Baxi engineer, ensures all components function correctly and identifies potential issues before they escalate. This includes checking the flue for blockages, verifying gas pressure, and inspecting the burner assembly.

Routine maintenance, like visually inspecting connections, can be performed by the homeowner. However, internal components should only be handled by professionals. Adhering to the manual’s recommended servicing schedule maximizes boiler lifespan and minimizes the risk of breakdowns, ensuring continued safe operation and optimal heating performance.

Annual Servicing Requirements

Annual servicing of the Baxi Bermuda back boiler must be conducted by a qualified Baxi-approved engineer. This comprehensive check includes a flue gas analysis to ensure efficient combustion and safe operation, verifying correct gas pressure, and inspecting the burner assembly for cleanliness and wear. The engineer will also assess the heat exchanger for corrosion and test safety devices like the pilot safety valve.

Crucially, the engineer will complete the Benchmark Commissioning Checklist, providing a record of the service performed. This documentation is vital for warranty purposes and demonstrates adherence to safety standards. Regular servicing maintains efficiency, prevents breakdowns, and ensures continued safe operation.

Cleaning the Burner Assembly

Cleaning the burner assembly is a critical part of Baxi Bermuda back boiler servicing, and should only be performed by a qualified engineer. Begin by isolating the gas supply and allowing the boiler to cool completely. Carefully remove the burner components, noting their positions for reassembly;

Use a soft brush and vacuum cleaner to remove dust, soot, and debris from the burner, pilot assembly, and gas injectors. Do not use abrasive cleaners or tools, as these can damage delicate components. Inspect the gas injectors for blockages and clear them with a fine wire if necessary. Reassemble the burner carefully, ensuring all parts are correctly positioned before relighting.

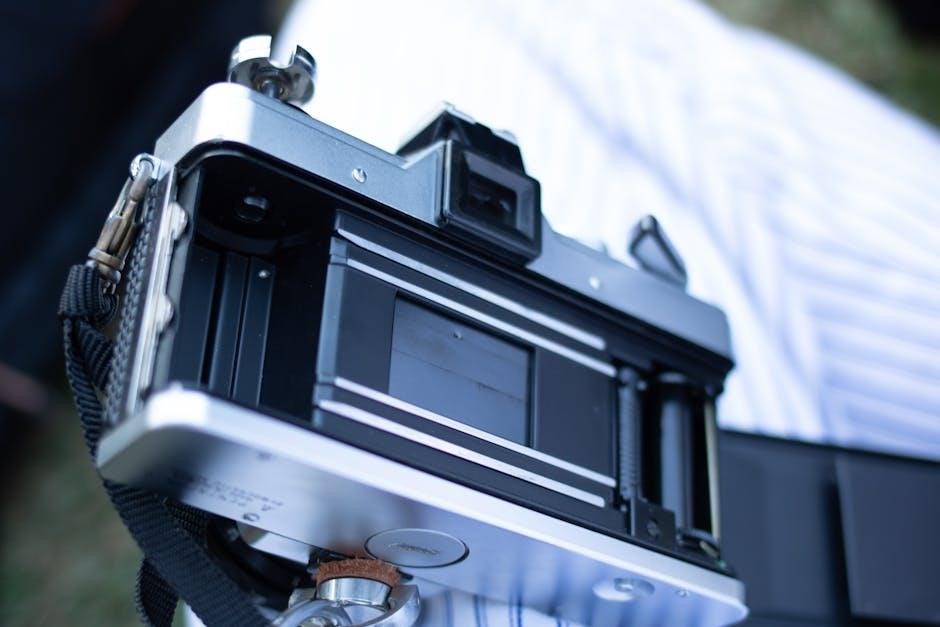

Parts Diagrams and Identification

Detailed parts diagrams are essential for Baxi Bermuda back boiler maintenance and repair. These diagrams illustrate the location and identification of all key components, including the burner assembly, heat exchanger, gas valve, and control unit. Accurate identification is crucial when ordering replacement parts, ensuring compatibility and correct functionality.

Refer to the official Baxi Bermuda manual or online resources for exploded views and part numbers. Understanding the diagram allows technicians to efficiently disassemble and reassemble the boiler, facilitating effective servicing. Always use genuine Baxi parts to maintain boiler performance and safety standards.

Gas Supply and Connections

Proper gas supply and secure connections are paramount for safe Baxi Bermuda operation. The boiler must be connected to a suitable gas supply, adhering to all local regulations and safety standards. Ensure the gas supply pressure matches the boiler’s requirements, as specified in the manual.

All gas connections should be leak-tested using an appropriate leak detection fluid after installation or any maintenance work. Qualified Gas Safe registered engineers must perform all gas-related work. Incorrect gas connections can lead to dangerous situations, including gas leaks and carbon monoxide poisoning. Always verify the gas type (natural gas or propane) is correct for the appliance.

Water System Integration

The Baxi Bermuda back boiler is designed for compatibility with both fully pumped and gravity hot water systems. For fully pumped systems, a suitable pump must be installed and correctly sized to ensure adequate hot water circulation. Gravity systems rely on natural convection, requiring proper pipework configuration for efficient operation.

Ensure the cold water supply to the boiler meets the required pressure and flow rate. Proper venting is crucial to prevent airlocks and maintain system efficiency. The manual details specific requirements for each system type, including pipe sizes and installation guidelines. Incorrect integration can lead to reduced hot water performance or system failure.

Fully Pumped Systems

When integrating the Baxi Bermuda with a fully pumped system, a correctly sized and installed pump is essential for optimal performance. The pump should be capable of providing adequate flow rate and head pressure to meet the hot water demand. Ensure the pump is wired correctly and protected by appropriate fusing.

The manual emphasizes the importance of proper pipework configuration to minimize flow restrictions. Air vents should be installed at high points in the system to prevent airlocks. Regular pump maintenance, as outlined in the servicing section, is crucial for continued reliability. Incorrect pump selection or installation can lead to insufficient hot water or system noise.

Gravity Hot Water Systems

For Baxi Bermuda installations utilizing gravity hot water systems, the manual stresses adherence to specific guidelines. A correctly sized cold water feed pipe is vital to ensure sufficient flow to the boiler during operation. The cistern must be positioned at an adequate height to provide sufficient head pressure for hot water delivery throughout the property.

Pipework must be carefully designed to avoid restrictions and maintain a consistent flow. The manual details the importance of avoiding sharp bends and ensuring sufficient pipe diameter. Regular inspection of the cistern and associated pipework is recommended as part of routine servicing to prevent leaks or blockages.

Propane Model Specifics

The Baxi Bermuda propane models require specialized attention during installation and servicing, as detailed in the manual. These units are specifically designed for use with propane gas and are not compatible with natural gas without a conversion kit and qualified engineer intervention.

Propane firefronts are only suitable for Baxi Bermuda 553 Propane Back Boiler appliances. The manual emphasizes the importance of checking gas tightness after any propane-related work. Proper ventilation is crucial, and the propane supply must adhere to all relevant safety regulations. Always consult the dedicated propane section of the manual for detailed instructions.

Troubleshooting Error Codes

The Baxi Bermuda back boiler manual doesn’t explicitly list detailed error codes in the provided snippets. However, common issues like pilot light failure or low pressure often manifest as operational problems rather than specific digital codes.

If the boiler fails to ignite, consult the manual’s section on pilot light operation and relighting. Low pressure problems require checking the system pressure and potentially repressurizing, following the manual’s instructions. For more complex faults, always consult a qualified Baxi service engineer. Referencing the full manual is crucial for diagnosing any unusual behavior.

Replacing Common Parts

The Baxi Bermuda back boiler manual doesn’t detail specific part replacement procedures within the provided text. However, routine servicing, as outlined in the manual, may necessitate replacing components like the burner assembly. Always ensure the boiler is isolated from the gas and electricity supply before attempting any repairs.

Due to the complexity of gas appliances, it’s strongly recommended that all part replacements are carried out by a qualified Baxi service engineer. Incorrect installation can be dangerous. Refer to the parts diagrams within the full manual for identification, and always use genuine Baxi parts to maintain safety and efficiency.

Finding a Qualified Baxi Service Engineer

The Baxi Bermuda back boiler, being a gas appliance, requires qualified personnel for servicing and repairs. The manual itself doesn’t provide a directory, but Baxi recommends using their official online engineer locator tool on the Baxi website. This ensures you find a service engineer specifically trained and certified to work on Baxi boilers.

Always verify the engineer’s credentials and insurance before allowing them to work on your appliance. A qualified engineer will possess the necessary expertise to diagnose issues accurately, replace parts safely, and ensure the boiler operates efficiently and in compliance with safety regulations. Avoid unqualified individuals for all manual-related tasks.

Useful Resources and Links

For comprehensive support regarding your Baxi Bermuda back boiler, the official Baxi website is the primary resource. It hosts downloadable manuals, frequently asked questions, and troubleshooting guides. Searching for “Baxi Bermuda 552/553 manual” will yield relevant documents.

Additionally, online plumbing and heating forums often contain discussions and advice from experienced users and qualified engineers regarding Baxi boilers. Remember to verify any information found on forums with official Baxi documentation or a certified service engineer. These resources can aid in understanding the manual and resolving common issues.

Warranty Information

Baxi typically offers a standard warranty on the Bermuda back boiler, covering manufacturing defects in materials and workmanship. The duration of the warranty can vary depending on the specific model and the date of installation, so consulting your original purchase documentation is crucial.

To ensure your appliance is covered, it’s essential to register your Baxi Bermuda boiler promptly after installation. This allows Baxi to contact you with important updates and facilitates any warranty claims. Keep your proof of purchase and the Benchmark Commissioning Checklist as evidence of the installation date and proper setup.

Registering Your Appliance

Registering your Baxi Bermuda back boiler is a vital step to validate your warranty and ensure access to crucial support and updates. This process typically involves visiting the official Baxi website and completing an online registration form. You’ll generally need details from your appliance, such as the model number, serial number, and the date of installation.

Having a registered appliance allows Baxi to efficiently handle any potential warranty claims and proactively inform you about important safety notices or service updates. Retain a copy of your registration confirmation for your records, alongside your proof of purchase and the completed Benchmark Commissioning Checklist.