LS Wiring Harness Instructions: A Comprehensive Guide

This guide simplifies LS engine swap wiring, offering step-by-step instructions and illustrations for a successful installation. It addresses common challenges and advanced integration techniques.

Understanding the LS Swap Popularity

The Chevrolet LS series small-block motor’s dominance in the hot rod community fuels the demand for straightforward swap solutions. Engine swaps increasingly favor the reliable small-block Chevy package, making dedicated wiring harnesses essential. LS swaps offer a potent combination of affordability and performance, attracting both seasoned mechanics and newcomers.

Many enthusiasts, often budget-conscious, initially hesitate due to perceived wiring complexity. However, simplified wiring solutions, like standalone harnesses, demystify the process. The LS engine’s versatility allows integration into diverse vehicles, further driving its popularity. Proper wiring ensures optimal engine function and avoids frustrating troubleshooting later on, solidifying the LS swap’s appeal.

The Chevrolet LS Series: A Hot Rod Staple

The Chevrolet LS series small-block is the most popular modern engine within the hot rod world, renowned for its power, reliability, and aftermarket support. Its simple design and readily available parts contribute to its widespread adoption in engine swaps. LS engines, like the LS3 and LS7, deliver impressive performance gains over older designs.

This popularity necessitates simplified wiring solutions for successful integration into various vehicles. A dedicated wiring harness eliminates the complexities of modifying factory systems, ensuring a clean and efficient installation. The LS engine’s adaptability makes it a favorite for projects ranging from classic car restorations to custom builds, driving continued demand for quality wiring harnesses.

Why a Dedicated Wiring Harness is Crucial

Modifying a factory harness for an LS swap is time-consuming and prone to errors. Cutting and splicing wires can introduce reliability issues and potential electrical conflicts. A dedicated harness streamlines the process, providing only the necessary connections for a standalone engine operation.

These harnesses eliminate unnecessary wiring, reducing weight and simplifying troubleshooting. They ensure proper compatibility with aftermarket components like ECUs and fuel injection systems. Investing in a quality harness saves time, minimizes headaches, and guarantees a secure, functional, and long-lasting LS engine swap, avoiding potential electrical gremlins.

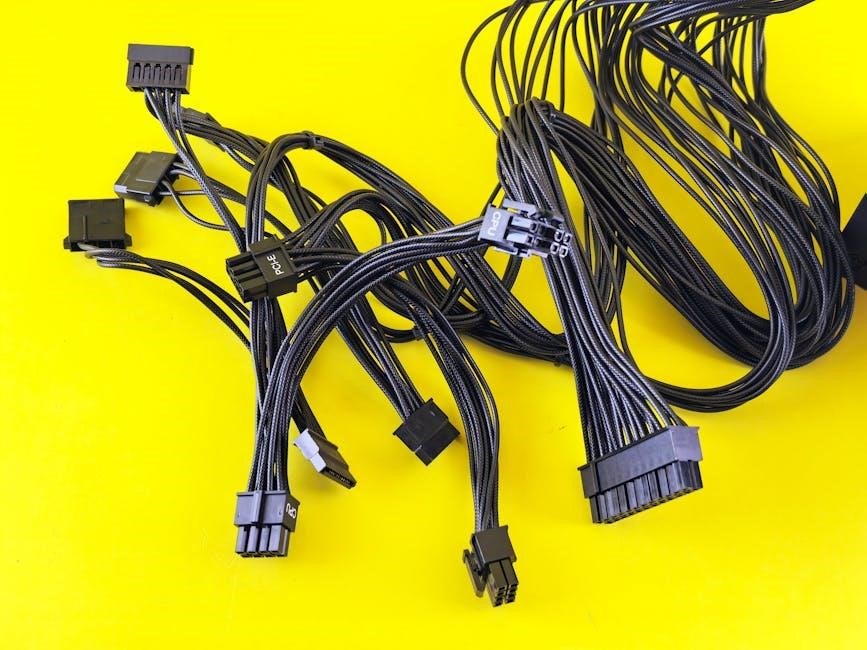

Types of LS Wiring Harnesses

LS harnesses vary: standalone, modified vehicle-specific (like Australian imports), and drive-by-cable (DBC) options exist, catering to diverse swap needs and budgets.

Standalone Wiring Harnesses

Standalone harnesses offer complete control and simplicity for LS swaps. These are purpose-built, not derived from factory systems, eliminating unnecessary wires. They typically include only the essential connections for running the engine – power, ground, sensors (MAP, TPS, crank, cam), fuel, and ignition.

This approach is ideal for custom builds or when integrating with aftermarket ECUs. Standalone harnesses require more initial wiring effort, as you connect everything directly, but they provide a cleaner, more organized installation. They often come with detailed instructions and color-coded wires to aid the process. Pace Performance offers such solutions, simplifying the daunting task of wiring an LS engine.

Modified Vehicle-Specific Harnesses (e.g., Australian Delivered Vehicles)

These harnesses start with a factory LS harness, often from Australian-delivered vehicles, and are modified for swap applications. They retain the factory connectors and wiring layout, simplifying integration in some cases. A Stage Two LS1 Conversion Harness is an example, offering a pre-wired solution.

Modifications typically involve removing unnecessary wires and extending others to reach the new engine location. This approach can be cost-effective, but requires careful attention to detail and a good understanding of the original wiring diagram. It’s crucial to verify all connections and ensure compatibility with your specific setup. These harnesses often require some degree of customization.

Drive-by-Cable (DBC) Harnesses

Drive-by-Cable (DBC) harnesses are designed for LS engines paired with a traditional throttle cable setup. These eliminate the need for a throttle body with an electronic motor and sensor. Creating a DBC harness involves repurposing or modifying an existing harness.

The process typically involves removing the DBW (Drive-by-Wire) components and wiring, then adapting the harness for a cable-operated throttle body. This often requires splicing and re-pinning connectors. DBC harnesses are popular for budget-conscious builds and offer a simpler installation compared to DBW systems. Careful attention to wiring diagrams is essential for a successful conversion.

Essential Tools and Materials

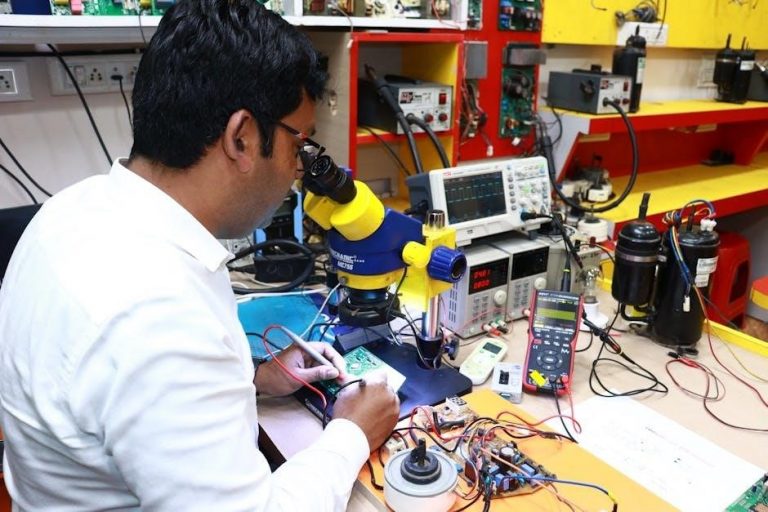

Successful LS swaps demand specific tools: wiring diagrams, crimpers, connectors, and a multimeter. Quality materials ensure reliable connections and accurate testing throughout the wiring process.

Wiring Diagrams and Documentation

Accurate wiring diagrams are absolutely critical for a successful LS swap. These diagrams detail every connection, color code, and component location. Chevrolet Performance documentation provides factory-level schematics, invaluable for understanding the original system.

Standalone harness suppliers, like Pace Performance, often include their own customized diagrams tailored to their specific harness. Online forums and communities are also excellent resources, frequently offering user-created diagrams and troubleshooting guides.

Thoroughly study the documentation before beginning any wiring work. Understand the function of each wire and its corresponding connection point. Proper documentation minimizes errors and ensures a safe, reliable installation. Don’t hesitate to consult multiple sources to confirm information.

Crimping Tools and Connectors

High-quality crimping tools are essential for creating secure and reliable electrical connections. Invest in a tool designed for automotive connectors, ensuring a proper crimp every time. A good crimp tool will create a gas-tight seal, preventing corrosion and ensuring conductivity.

Use the correct connectors specified for your harness. Common connector types include Weather Pack, Metri-Pack, and Deutsch connectors. Matching the connector to the wire gauge is crucial for a secure fit.

Stock up on a variety of connectors, terminals, and heat shrink tubing. Properly sealed connections protect against moisture and vibration, ensuring long-term reliability. Avoid cheap connectors, as they can lead to connection failures.

Multimeter for Testing

A digital multimeter is indispensable for verifying wiring integrity and diagnosing electrical issues. Before connecting the harness, use the multimeter to check for continuity in each wire, ensuring no breaks or shorts exist. Confirm proper voltage at power sources and ground connections before connecting sensitive components.

Utilize the multimeter’s voltage, resistance, and continuity testing functions throughout the installation process. Testing sensors like MAP, TPS, and crank position sensors verifies their functionality and proper wiring.

Always disconnect power before performing any electrical tests. A multimeter helps pinpoint shorts to ground or open circuits, saving time and frustration during troubleshooting.

Step-by-Step Installation Guide

Follow this guide for a smooth LS swap! It details component identification, power/ground connections, sensor wiring, and fuel/ignition system integration for success.

Identifying Key Components

Before starting, familiarize yourself with the LS harness’s core elements. Locate the main power feed, ground points, and the ECU connector. Identify crucial sensors like the MAP, TPS, crank, and cam position sensors, noting their respective wiring colors.

Understand the fuel pump relay, injector connectors, and ignition coil wiring. A bulky harness is common, especially from Australian delivered vehicles, so organization is key. Disconnect the battery before any work! Carefully trace each wire, referencing wiring diagrams to understand its function. Knowing these components upfront streamlines the installation process and minimizes potential errors during connection.

Power and Ground Connections

Establishing solid power and ground is paramount. Connect the main power feed from the battery to the designated harness wire, using appropriately sized fuses. Secure multiple ground connections to the chassis, ensuring clean, corrosion-free contact. Poor grounding causes numerous issues.

Verify voltage at the ECU connector to confirm power delivery. Double-check all connections for tightness and insulation. A dedicated wiring harness simplifies this, avoiding splicing into the vehicle’s existing system. Remember, a reliable power and ground foundation is crucial for the entire LS swap to function correctly and prevent electrical gremlins.

Sensor Connections (MAP, TPS, Crank, Cam)

Accurate sensor data is vital for proper engine operation. Connect the Manifold Absolute Pressure (MAP), Throttle Position Sensor (TPS), Crankshaft Position Sensor, and Camshaft Position Sensor wires according to the wiring diagram. Incorrect connections lead to performance issues.

Ensure each connector is fully seated and secured. Verify sensor signals with a multimeter to confirm functionality. A standalone harness typically color-codes these wires for easier identification. Pay close attention to pin assignments, as they vary between engine generations. Proper sensor wiring guarantees optimal fuel delivery and ignition timing.

Fuel System Wiring

Fuel system wiring involves the fuel pump relay, fuel pump, and potentially fuel injectors. Connect the fuel pump relay to a switched power source and ground. Ensure the fuel pump receives adequate voltage for reliable operation. Injector wiring requires precise connections to the ECU, following the designated pinout.

Use the correct gauge wire for the fuel pump to handle the current draw. Verify polarity before connecting the fuel pump. Double-check all connections for secureness and insulation to prevent shorts. Proper fuel system wiring is crucial for delivering the correct amount of fuel to the engine.

Ignition System Wiring

Ignition system wiring centers around the coil packs and crank/cam sensors. Connect each coil pack to its designated output from the ECU, ensuring correct firing order. The crank and cam sensors provide vital timing information; connect them to the ECU inputs as specified in the wiring diagram.

Proper shielding of ignition wires is essential to prevent interference. Verify the correct polarity of the crank and cam sensor connections. Securely mount the coil packs and route the wires away from heat sources. Accurate ignition wiring guarantees proper engine timing and efficient combustion.

Addressing Common Challenges

Decoding wiring colors, troubleshooting connections, and managing bulky harnesses are typical hurdles. Patience, diagrams, and proper tools are key to overcoming these issues effectively.

Decoding the Wiring Colors

Understanding LS wiring color codes is crucial for a successful swap. Chevrolet doesn’t always follow a consistent pattern, making it potentially confusing. Often, colors repeat for different functions across various LS engine models. Referencing accurate wiring diagrams is absolutely essential; don’t rely on assumptions!

Common colors include red for power, black for ground, and various shades for sensors. However, a red wire isn’t always positive, and a black wire isn’t always ground. Online forums and supplier documentation (like Pace Performance) provide valuable color code charts specific to different LS generations and applications. Carefully trace each wire back to its source to confirm its function before making any connections.

Troubleshooting Connection Issues

Connection problems are common during LS swaps. Begin by visually inspecting all connections for looseness, corrosion, or improper crimping. Use a multimeter to verify voltage and continuity at each connector; A lack of voltage indicates a power supply issue, while a lack of continuity suggests a broken wire or bad connection.

If the engine doesn’t crank, check the starter relay and solenoid wiring. For no fuel delivery, inspect the fuel pump relay and wiring. Sensor issues often manifest as poor running or no-start conditions; verify sensor signals with a scan tool. Online forums are invaluable for diagnosing specific problems encountered by other enthusiasts.

Dealing with Bulky Harnesses

LS engine harnesses can be notoriously bulky, especially those from factory applications. Careful routing is crucial to avoid damage and ensure adequate clearance. Consider removing unnecessary wiring for a cleaner installation, but only if you understand its function. Securing the harness with zip ties or harness tape prevents chafing and movement.

Repackaging the harness can significantly reduce its size. Utilize a heat gun to shrink wrap sections, creating a more compact profile. Standalone harnesses are often less bulky than modified factory harnesses. Proper organization during installation minimizes clutter and simplifies future troubleshooting.

Advanced Considerations

Explore ECU integration, DBW modifications, and LS-PrePost simulation for optimized performance. These techniques demand expertise and a thorough understanding of the LS system.

Integrating with Aftermarket ECUs

Transitioning from the factory ECU to an aftermarket system requires careful wiring harness adaptation. Many standalone ECUs demand specific input signals and control outputs, necessitating modifications to the LS harness. This often involves identifying and repurposing wires for functions like fuel injection, ignition timing, and variable valve timing control.

Carefully consult the aftermarket ECU’s wiring documentation and compare it to the LS harness pinout. Utilize high-quality connectors and soldering techniques to ensure reliable connections. Consider using a wiring diagram specifically designed for your ECU and LS engine combination. Proper calibration of the ECU is crucial after wiring is complete, ensuring optimal engine performance and preventing damage.

Drive-by-Wire (DBW) Harness Modifications

Drive-by-Wire (DBW) systems present unique wiring challenges due to the electronic throttle control. Modifying a harness for DBW often involves integrating the throttle position sensor (TPS) signal and the throttle actuator motor control wires with the aftermarket ECU. Ensure compatibility between the ECU and the DBW throttle body, as some systems require specific calibration procedures.

Carefully identify the DBW harness connectors and their corresponding functions. You may need to add or modify wires to provide the ECU with the necessary throttle control signals. Proper wiring and calibration are essential for smooth throttle response and preventing unintended acceleration or deceleration.

LS-PrePost Software for Simulation

While primarily a pre- and post-processor for simulations, LS-PrePost can indirectly aid LS wiring harness projects. It’s not directly used for wiring diagrams, but its capabilities in visualizing complex geometries can be applied to harness routing. Understanding the engine bay’s physical space is crucial for planning a clean and efficient wiring layout.

LS-PrePost allows for the import of CAD models of the engine and surrounding components, enabling visualization of potential harness pathways. This can help identify potential interference points and optimize harness length, reducing clutter and improving reliability. It’s a powerful tool for advanced planning, though a dedicated wiring diagram software remains essential.

Resources and Support

Online forums and suppliers like Pace Performance offer invaluable assistance. Chevrolet Performance documentation provides detailed wiring schematics for LS engines and related components.

Online Forums and Communities

Engaging with online LS swap communities is incredibly beneficial. Forums dedicated to engine swaps, like those found on dedicated hot rod websites, provide a platform to ask questions, share experiences, and learn from others who have tackled similar projects. These communities often have dedicated threads specifically addressing LS wiring harness challenges, offering solutions to common problems and insights into best practices.

Members frequently share wiring diagrams, troubleshooting tips, and even custom harness modifications. Searching these forums can often reveal answers to specific questions regarding your setup. Don’t hesitate to post your own questions – experienced members are usually eager to help newcomers navigate the complexities of LS wiring. Active participation can significantly streamline your installation process and prevent costly mistakes.

Pace Performance and Similar Suppliers

Companies like Pace Performance specialize in LS swap components, including pre-made wiring harnesses. They offer a range of harness options, from basic standalone units to more complex, vehicle-specific designs, eliminating the need for extensive wiring modifications. These harnesses are often designed to simplify the installation process and ensure compatibility with various LS engine configurations.

Other reputable suppliers provide similar products and support. When choosing a harness, consider the specific requirements of your swap, including engine type, transmission, and desired features like drive-by-wire. Suppliers often offer technical support to assist with installation and troubleshooting, making them a valuable resource for DIY enthusiasts. Researching different suppliers and comparing their offerings is crucial.

Chevrolet Performance Documentation

Chevrolet Performance offers comprehensive documentation for its LS and LT engines, including detailed wiring diagrams and installation guides. These resources are invaluable for understanding the intricacies of the engine’s electrical system and ensuring a correct installation. Accessing this documentation can significantly reduce troubleshooting time and prevent potential issues.

The documentation often covers specific wiring configurations for different engine models and applications. It provides information on sensor locations, connector pinouts, and wiring harness layouts. Utilizing these official resources alongside aftermarket harness instructions is highly recommended for a successful LS swap. Chevrolet’s support materials are a cornerstone of a well-executed project.